WHERE THE PASSION IS BUILT

The Cassino Plant

Come with us inside the Cassino Plant, where Giulia and Stelvio are built, learn more about how we create these cars and get to know the people involved in this process.

Introduction

Driving an Alfa Romeo is an unmatchable experience. But where does that emotion come from? Come with us inside the Cassino Plant, where Giulia and Stelvio are built, and meet the people who put their passion into creating our high-quality cars every day.

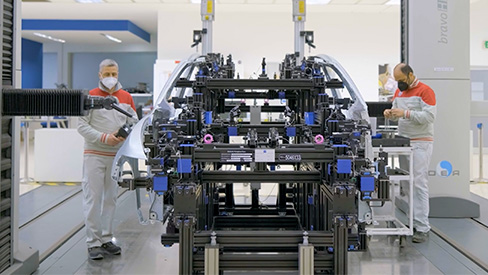

Robots and automated processes

How can we craft such lightweight bodywork for Giulia and Stelvio? By using automated processes and advanced robots that can handle high-quality materials like aluminium and high-strength steel, we are able to guarantee great driving pleasure on each Alfa Romeo. Watch the video to see them in action.

The Biolake

At the Cassino Plant, our people actively cooperate with nature, to make the facility sustainable and to protect the biodiversity of the area, thanks to the biolake: an artificial basin that naturally filter all the water used in the production process, with the aid of the vegetal species that live around and in it. But not only the biolake allows us to have zero environmental impact on the water system, it also contributes to the lives of many vegetals and animals, helping them prosper.

System Efficiency

The advanced machinery in our Cassino Plant allows us to carry out delicate operations, like the cataphoresis and the spraying of the layers of paint, sensibly reducing our environmental footprint.

Waste Management

Dealing with waste in a careful way can greatly affect the environmental impact of any activity. Today we manage to send no waste to landfills thanks to the right initiatives and following our five principles – REFUSE, REDUCE, REUSE, RECYCLE, RECOVERY.

Welcome To Pomigliano

Discover how the processes of the Pomigliano Plant were innovated both from the point of view of technology and sustainability to produce the new Tonale Hybrid, that marks the beginning of a new era for Alfa Romeo. Start a journey with us and meet those who every day put their passion into building the amazing driving experience that identify our cars.

Hybrid Assembly Chain

To build an innovative car you need an innovative plant. That’s why in Pomigliano D’Arco we completely renovated the assembly chain to produce the new Tonale Hybrid. First of all, we focused our attention on creating the best work environment, believing that a comfortable workstation allows every worker to better express themselves, producing a better output. Also, to ensure the best quality of our product we followed three main principles: the formation of our people, the digitization of the industry, and the dynamic testing of 100% of our cars.

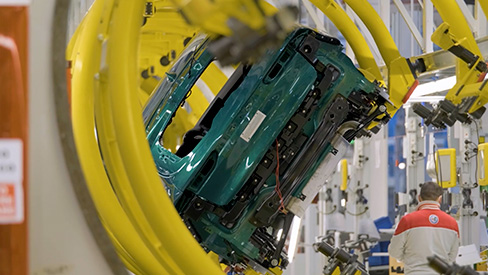

Plasma Cutting

To produce the new Alfa Romeo Tonale Hybrid, also the bodywork area of the Pomigliano Plant was deeply renovated. How? With new highly automated plasma-cutting technologies, that employ robots to shape car bodies with a tailoring level of precision, guaranteeing a top manufacturing quality and a reduction in CO2 emissions and risk for operators.

Metrological Room

Also known as the “zero tolerance room”, the metrological room is the place where we evaluate whether a piece conforms to the project or not. In this area, engineers and operators test together every single component of the new Tonale Hybrid and, if necessary, find an immediate solution to each problem.

Sustainability

The daily activities at the Pomigliano Plant can be described as sustainable since they are based on the ideas of biodiversity, circular economy, respect for the environment, and reduction of waste and CO2 production. The good quality of air and soil is highlighted by the fact that many different vegetal and animal species can live in the surroundings and inside the facility. Being more sustainable and respectful of the environment is a core element of our Brand strategy: we aim at producing cars that have a lower impact on the planet, but also at lowering our own impact at the plant while producing our cars.

By using Youtube player, you as a user of this website are subject to the Youtube Additional Terms of Use.